Making Beautiful Design Choices Easy

An experienced, dedicated team behind-the-scenes makes sure customers and designers have easy access to more choices.

The leaders of a 60-year-old, multi-billion dollar, global company know it takes great people, new ways of thinking and a few reinventions to stay ahead. Right now, they are in the midst of a significant investment to reimagine their workplace for the next generation. They are tackling all the big issues facing business today driven by digital transformation — a tight labor market, the need for new types of skills, quick changing market conditions and aggressive competition.

They want their new space to be attractive, flexible and support different kinds of work their people do throughout the day. They’re moving from mostly private offices and siloed teams to a more mobile, collaborative culture that includes more social, relaxed and creative spaces away from the traditional desk.

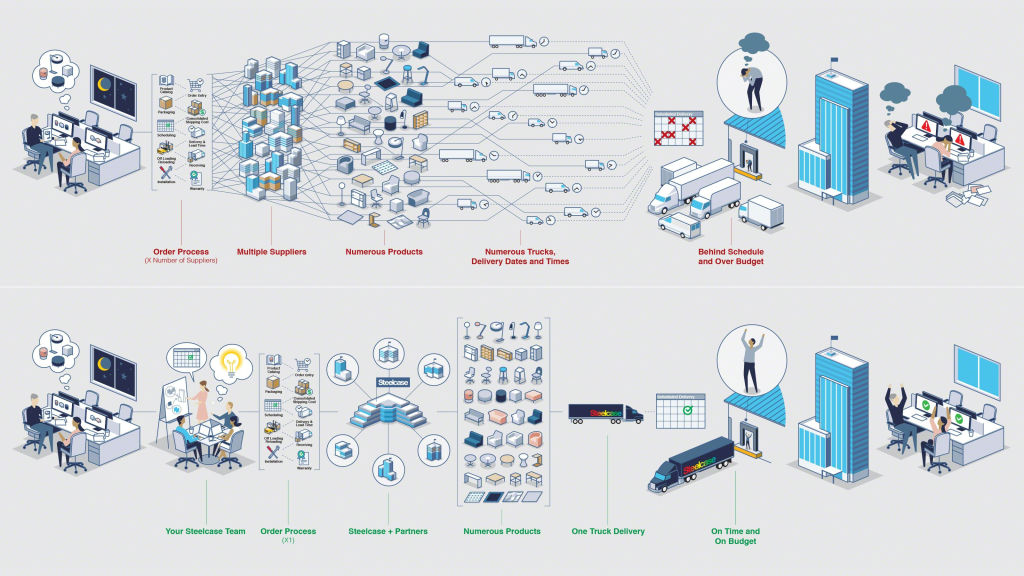

It’s Complicated

After working with well-respected global architecture and design firm, Gensler, they landed on a plan everyone is excited to realize. But, in their effort to create different kinds of spaces to support focus work, small and large group meetings, social connections and respite, it’s far from simple.

They initially planned to use 128 different kinds of products from 50 different companies.

For every supplier added to a project, complexity increases. So, how could designers still provide a breadth of choices while also limiting risk, reducing costs and giving the client peace of mind?

This is a key question because each company handles the following differently:

- Customer portals

- Product catalogs

- Order entry process

- Order tracking

- Order management tools

- List price

- Discount

- Packaging

- Freight cost

- Cost of moving

- Warranty

- Lead time

There are so many factors to consider for packaging alone: dimensions, pick-up location, site information, number of boxes per product, labeling and more. Since most trucks leave the manufacturer carrying partial loads, product needs to go to a distribution warehouse where it is off-loaded and then reloaded onto another truck that will head to the project site.

Added Risk and Cost

For each of those 50 manufacturers, that’s added risk and added cost. There’s a greater potential for freight damage. There’s the cost of double-handling product and larger offloading costs. There’s risk the product won’t make it on time and miss it’s installation window.

On top of everything else, the tight labor market is impacting construction. If the products don’t make it on time, there’s no way of knowing how far this could set the project back. It’s added stress and worry about incurring additional costs and how it will affect the timeline 50 times over, once for each company involved in the project.

For architects and designers, the complicating factors are different, but in no way lessened. Each company requires due diligence (which often means multiple calls, emails and more time) to determine:

- List price

- Manual input of pricing

- Discount available

- Manual input of discount

- Fabric rep

- Fabric price

- Yardage on COM

- Freight

- Overall cost

“This is where we are able to help and make it so much easier on the customer and the designer,” says Brian Shapland, Steelcase general manager for ancillary partnerships. “Our partner network means we can meet the designer’s unique vision, save them time and eliminate unnecessary risks for the customer.”

An Easier Alternative

Since 2016, Steelcase has developed a carefully-curated collection of some of the world’s most iconic design brands to offer a wide variety of aesthetics and prices. Companies like West Elm, FLOS and Bolia are all available with the ease and reliability of the Steelcase distribution network.

Steelcase dealer McCoy-Rockford, based in Houston, came to the project with tremendous experience in the region. They worked closely with Steelcase to offer their client an alternative solution — one that mitigated risk and met their design expectations.

“Once the client and design firm realized we could provide everything they needed to keep the design in tact down to the very last details and do it all with one family of brands instead of 50, saving them time and money, their decision was clear,” says Ken Beaver, president and CEO, McCoy-Rockford.

Because it all would come from Steelcase, everything would ship together. It would arrive at the same time, be color coded by floor and go directly from the truck to where it would live. The calculated savings in time and money rang in at about $1 million.

“We know choice is key in creating inspiring, informal spaces where people want to work,” says Shapland. “But, that shouldn’t mean you have to pay more or spend more time tracking down details and logistics.”

Behind-the-Scenes of Simple

What sounds simple has taken years of work behind-the-scenes.

“It starts with an infrastructure that allows our dealers to order and schedule partner products just like they do Steelcase products,” says Brad Vernier, vice president, Steelcase global order fulfillment. “Before launching a new partner, teams are busy working with the partner to collect product data so that order entry functions correctly, dealers receive their order acknowledgments and everything else that they expect.”

Before any orders are entered, there needs to be a way to capture key data from all of the partners and their products. They need packaging information, dimensions and weight in addition to pick-up and delivery information. They also need site information like is there a loading dock and equipment available? Each piece of data is crucial.

“Every single partner has a project manager that’s asking the right questions to find any gaps that might exist in the logistics and fill them. It’s those small gaps that keep us up at night.”

Jill BoundsSteelcase Lean-Quality Manager

The operations team has daily meetings before launch. Then, weekly check-ins and monthly reviews. They address anything they didn’t anticipate and continue to monitor and learn throughout the early phases of ordering.

“We learn and test with small shipments to our facilities before launching to all our customers, so we know we’re ready to deliver,” said Bounds.

Following order entry, scheduling and data collection, there’s logistics planning. More than a century of experience allows operations teams to track weather, traffic, webcams, social media and news events to identify, predict and solve problems before they happen. Regional distribution centers allow teams to adjust so customers don’t have to. They manage 3,000 customer deliveries weekly and 150,000 products daily to 78,000 customers around the world. They do it with a near-perfect complete shipment rate of 99.93 percent.

Once the customer has what they need, the team isn’t done. They coordinate any warranty or after sale claims. Different partners have different agreements. But, the Steelcase team makes sure it’s easy to know who to call and how to resolve any questions.

Creating something simple is not easy. But, when the goal is to help people have a better day at work, it’s essential because design and delivery go hand-in-hand.